|

Vuototecnica News - Issue 142 - October 2024 Your Vacuum Solution Catalogue |

|

PVP PNEUMATIC VACUUM GENERATORS AND VACUUM CLAMPING TABLES FOR WOODWORKING

Vuototecnica, which has always been committed to working with its partners to develop cutting-edge solutions, is helping to improve efficiency and reduce operating costs for end customers. A concrete example of this synergy can be found in a recent application developed in the Brianza area, renowned for its prestigious furniture makers, a particularly suitable territory for the introduction of solutions that aim to improve the quality of processing.

More...

|

|

NEW BELLOWS SUCTION CUP FOR PHARMA AND PACKAGING INDUSTRIES

Vuototecnica introduced a new bellows suction cup (code 01 05 09), designed to offer adaptability and optimal performance particularly in the Pharma and Packaging industries. The suction cup, with ½ bellows of 5mm diameter, handles delicate or irregular objects with ease, such as sheet metal, labels, metal and plastic small parts, vials, syringes, tablets, capsules and other delicate products. It has the characteristic of withdrawing on contact with the surface to be handled, with the activation of vacuum, thus creating a rapid lifting motion that prevents the load underneath from sticking to the one being lifted.

More...

|

|

| Applications and solutions with Vuototecnica products |

|

MANIPULATING STAINLESS STEEL TUBULARS SAFELY

The manipulation of hundred pounds stainless steel tubulars, such as those that you can see in the video, can be very complex, and because there exists the need to adapt to different diameters and weights, and because there is need for a constancy in the vacuum flow, even in case of sudden blackout of the electric line. Vuototecnica solved the problems of its customers through the use of a security depressor with two pumps capable of maintaining a constant flow rate and the degree of vacuum in every moment.

More...

|

|

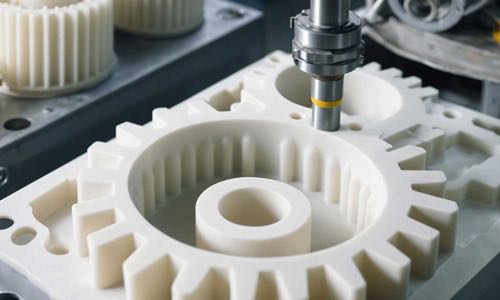

VACUUM CASTING: INNOVATION AND FAST PROTOTYPING

Vacuum casting is an advanced process that allows prototypes and small batches of plastic or metal parts to be produced using the vacuum. A liquid material is poured into a silicone mold and is left to solidify while air is removed from the mold so that the object takes on the desired shape and quality. Because of the fine reproduction of details, it is a perfect choice for low-volume production cycles with tight tolerances, although it has the disadvantage of excluding heat- or pressure-sensitive materials.

More...

|

|

|

|

You are receiving this newsletter because you are registered in our database.

To cancel your subscription, select the "Unsubscribe" link below. |